Welcome...

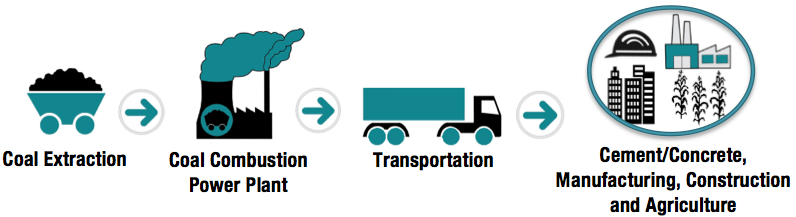

Australian producers and marketers of power station ash formed the Ash Development Association of Australia (ADAA) with the objective of investigating and developing market opportunities for the use of these materials in various industry applications such as construction, agriculture and manufacturing.

While the principal output from coal combustion is energy, significant quantities of by-products in the form of coal combustion products (CCPs) are also produced. In life cycle terms, the opportunities to exploit the low energy embodied in CCPs such as fly ash, furnace bottom ash, boiler slags and cenospheres are extensive.

The combustion of pulverised coal in the furnace of a coal-fired power station boiler results in the production of a number of solid by-products. Internatioanlly we now more accurately classifiy these inert solid by-products as coal combustion products. This term reflects a more positive view and is in keeping with circular economy concepts, being an industrialised approach that seeks to use one industry's by-product output as another industry's material inputs.

We trust you find this website resource helpful, moreover gain a better understanding of coal combustion products which are man-made minerals that can help conserve finite natural resources.